Process

About Wood & the Finished Product

The Wood

Most woods are harvested locally by land owners that contact me via various means. They want to see something useful made with it. Compensation varies.

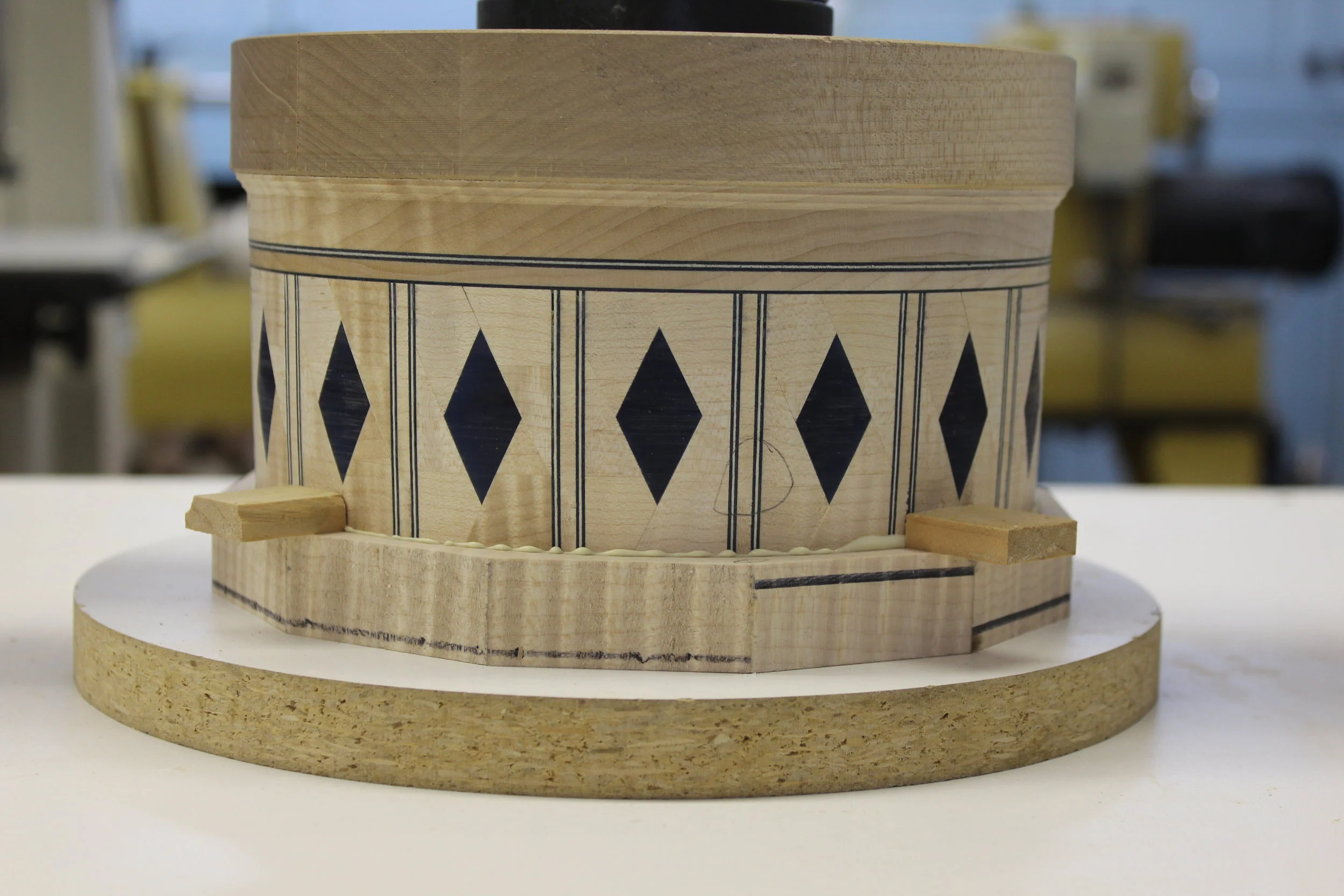

Fresh cut wood, is referred to as “green” and is very high in water content. The wood is cut to size using a chainsaw with specific attention to grain orientation in an effort to maximize the beauty, balance and aesthetics of the wood. Then it is cut into a round on the bandsaw with further adjustments to the grain orientation. From there, it is rough turned on the lathe leaving room for a future turning.

Bowl blanks are then air dried 3 to 6 months. Dry time depends on wood type and the time of year harvested. When dry they are turned to their final shape and dimension, which is referred to as a “twice turned” bowl.

Yarn bowls have custom “J” hooks that are hand drawn, sawed out by hand and sanded to 400 grit to avoid any catches of yarn as it’s drawn through the hook.

All bowl types are turned by hand, unique and one of a kind pieces. All pieces are signed or initialed and marked with the wood type used for that specific item.

The Finish

Finish #1. Waterlox is a penetrating oil finish made from Tung Oil. It is a long lasting durable finish made to last generations. Several coats of “Waterlox” finish is applied and then each piece is buffed out using two types of buffing compound with a final buff using carnauba wax. Carnauba is one of the hardest waxes known to mankind that leaves a long-lasting smooth silky finish. This is my preferred finish for decorative pieces, center pieces, functional pieces like yarn bowls, and salt/pepper mills.

Finish #2. Walnut Oil can be used for wooden articles that make contact with food i.e. butcher blocks, salad bowls, kitchen utensils. I use 100% high linoleic acid walnut oil developed for woodworkers which is naturally high in two key fatty acids that help the oil polymerize. This is absent in culinary walnut oils. The oil is heat-treated to remove the proteins that may cause allergic reactions to those predisposed to them. Oil finishes are much easier to apply than film based finishes and anyone can replenish the finish. Nut, linseed, and Tung oils will harden and become part of the wood.

Finish #3. Chopsticks are treated with a special blend of mineral oil and beeswax. Hand wash with mild soap and water. When finish shows signs of wear, re-treat with a liberal application of mineral oil or walnut oil.

Directions on how to apply walnut oil:

Apply one heavy coat using a clean cloth or paper towel. Let it sit for an hour and then wipe away any excess. Your item is now ready to go. If the item begins to look dry over time reapply another coat.

How to care for your bowl.

Gently hand wash using a mild dishwashing liquid with a soft sponge or washcloth. Hand or air dry. Do not place in a dishwasher, oven or microwave.